3ddruckboss

Mingda AD-F4 channel letters 4-color

Mingda AD-F4 channel letters 4-color

Couldn't load pickup availability

MINGDA AD-F4 – Industrial 4-color 3D printer for signage & LED letters

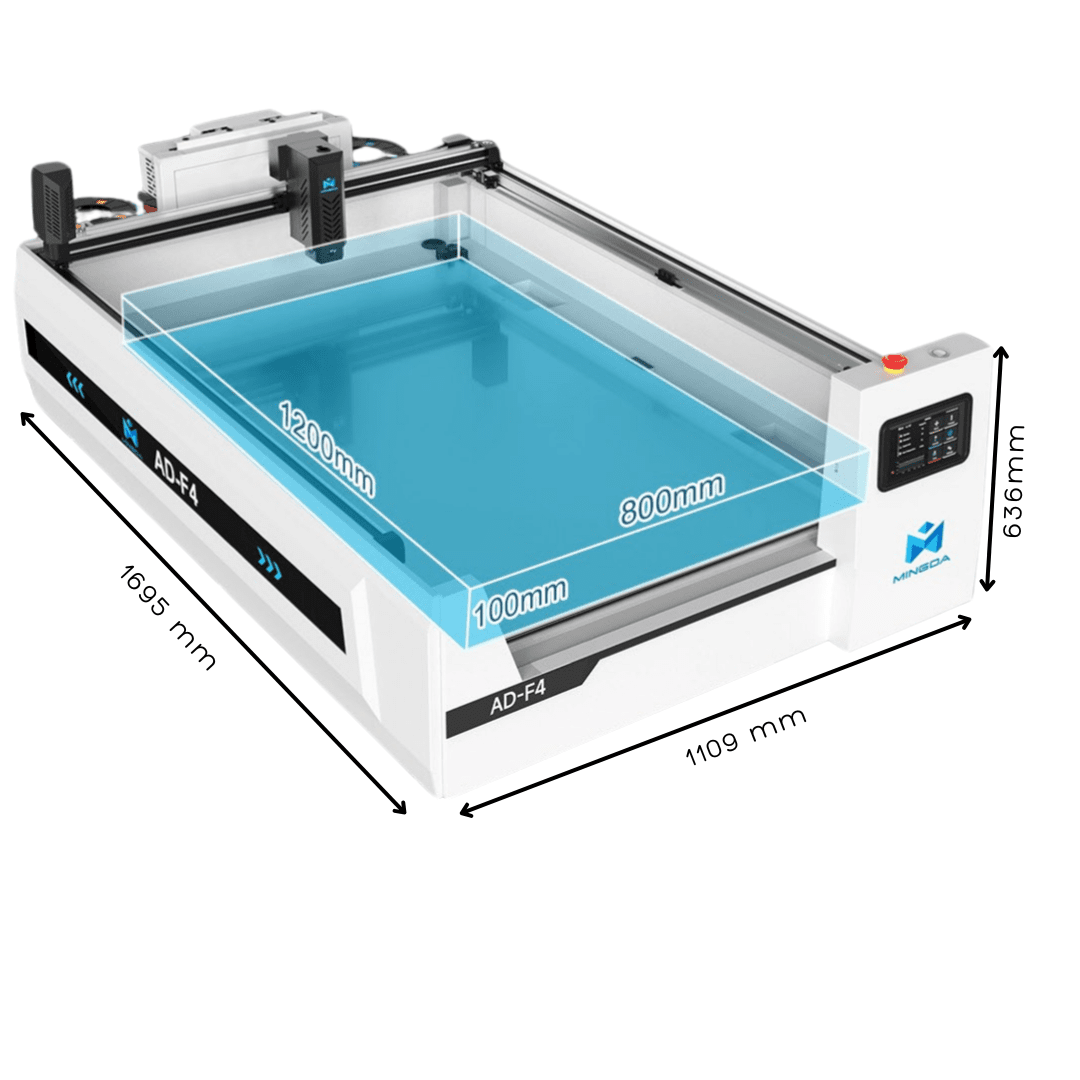

The MINGDA AD-F4 is a large-format, highly productive 3D printer with an automatic four-color change system (IMS), clipper control, and an enormous build volume of 1200 × 800 × 100 mm. Designed specifically for advertising technology, signage, and LED letters, it delivers color-intensive results, short turnaround times, and reliably high quality in series production.

Highlights

- 4-color printing (IMS): Automatic color change for multi-colored letters and signs without manual intervention.

- Clipper & High-Speed: Print speed up to 300 mm/s, peak acceleration 10,000 mm/s², max. flow 40 mm³/s.

- Huge build volume: 1200 × 800 × 100 mm – ideal for large-format letters, logos and lightbox components.

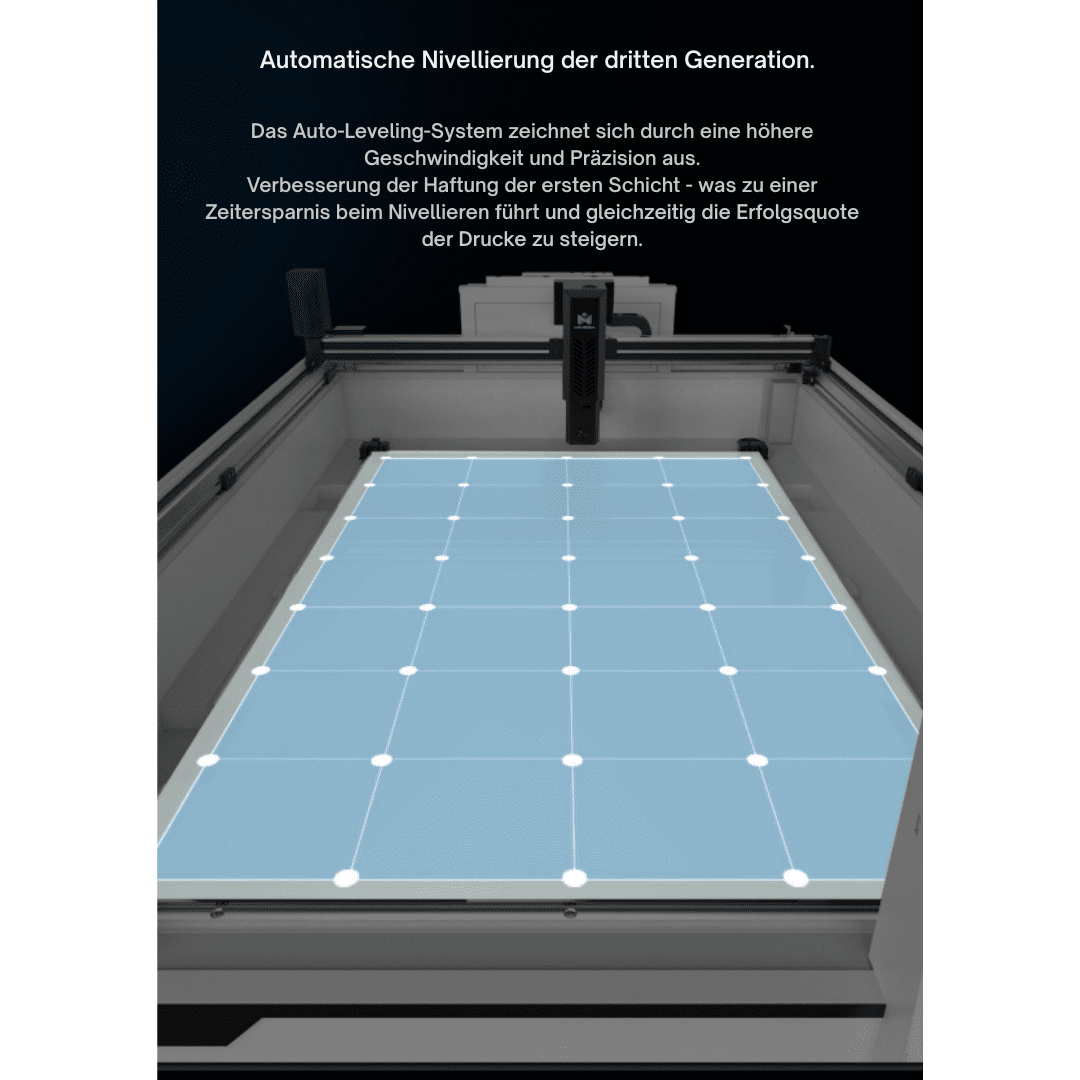

- Process reliability: 3rd generation auto-leveling, input shaper for vibration reduction, filament sensor & recovery after power failure.

- Air-heating bed: Air-heated build platform with tempered glass – fast heating, less warping, clean first layers.

- Proprietary software suite: Intuitive slicing, 2D-to-3D functions, vector import, and text generation for efficient signage workflows.

- Remote control & monitoring: Convenient monitoring and control of the printing process in everyday production.

Advantages in advertising technology

- Faster orders: High speed reduces production times – ideal for series and short-term campaigns.

- Less rework: Stable first layer, clean surfaces, reproducible quality.

- More creativity: Four colors in the process, free font and vector generation, flexible wall/floor thicknesses.

- Calculation reliability: Consistent processes reduce waste and secure deadlines.

Typical applications

- LED letters (front/side/back components)

- Logos, pictograms, signposts and POS displays

- Lightbox components and large-scale signage

Technical data

| Installation space | 1200 × 800 × 100 mm |

|---|---|

| Machine dimensions | approx. 1109 × 1695 × 636 mm |

| Print speed | up to 300 mm/s (typical high speed 200 mm/s) |

| acceleration | up to 10,000 mm/s² (0.035 s from 0 to 300 mm/s) |

| Max. material flow | 40 mm³/s |

| Color/material system | IMS four-color feeding (automatic color change) |

| nozzle | 0.8mm (standard); optional 0.4mm/0.6mm |

| Nozzle transfer temperature (max.) | up to 350 °C |

| Bed temperature (max.) | up to 60 °C (air-heated bed, tempered glass) |

| Supported materials | PLA, PETG, PDS (1.75 mm) |

| Orientation & Quality | Input shaper, 3rd gen auto-leveling, precise first layer |

| Control / Software | Klipper firmware; MINGDA Slicer & AdWordCraft |

| Comfort & Safety | Filament sensor, print continuation after power failure, remote monitoring |

Note: Specifications according to manufacturer's instructions. Subject to change.

Optimized workflow for LED letters

- Create font/logo as vector (e.g. DXF/SVG), define colors and wall thicknesses.

- Configure components (side walls, floors) specifically; use Prime Tower for clean color changes.

- Configure up to four filaments, start the print job and monitor the process.

FAQ

Can the AD-F4 print in multiple colors without stopping?

Yes. The IMS system automatically switches between up to four filaments without manually interrupting the job.

Which nozzles are available?

The standard setting is 0.8 mm for high productivity. 0.4 mm and 0.6 mm are optionally available for finer details.

How is warpage reduced in large parts?

The air-heated build platform (air-heating bed) evenly heats the build surface, thereby reducing warping and misprints.

Is it possible to continue printing after a failure?

Yes. Printing can be resumed at the point where it was interrupted after a power outage or filament run out.

For ambitious signage projects

Whether for a one-off production or series production: The MINGDA AD-F4 delivers fast, colorful and reliable results – ideal for advertising technology, trade fair construction and retail.

Share