3ddruckboss

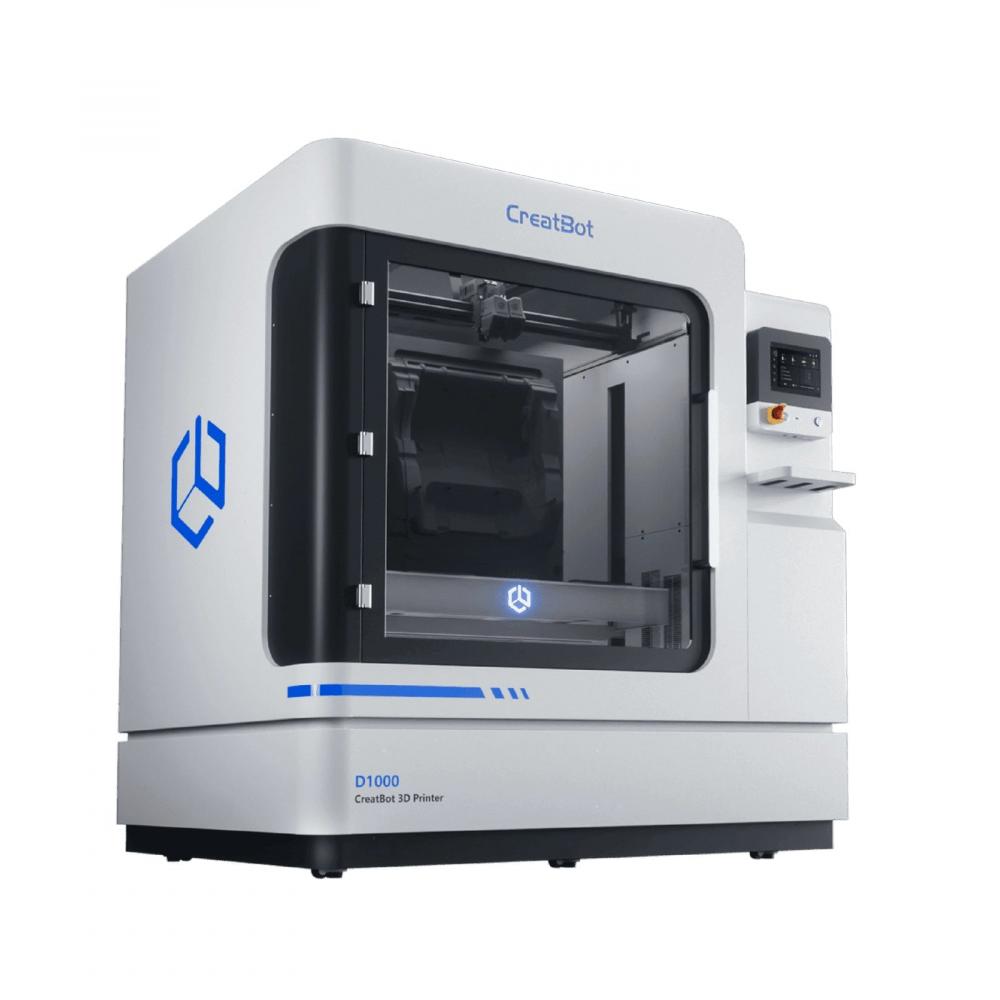

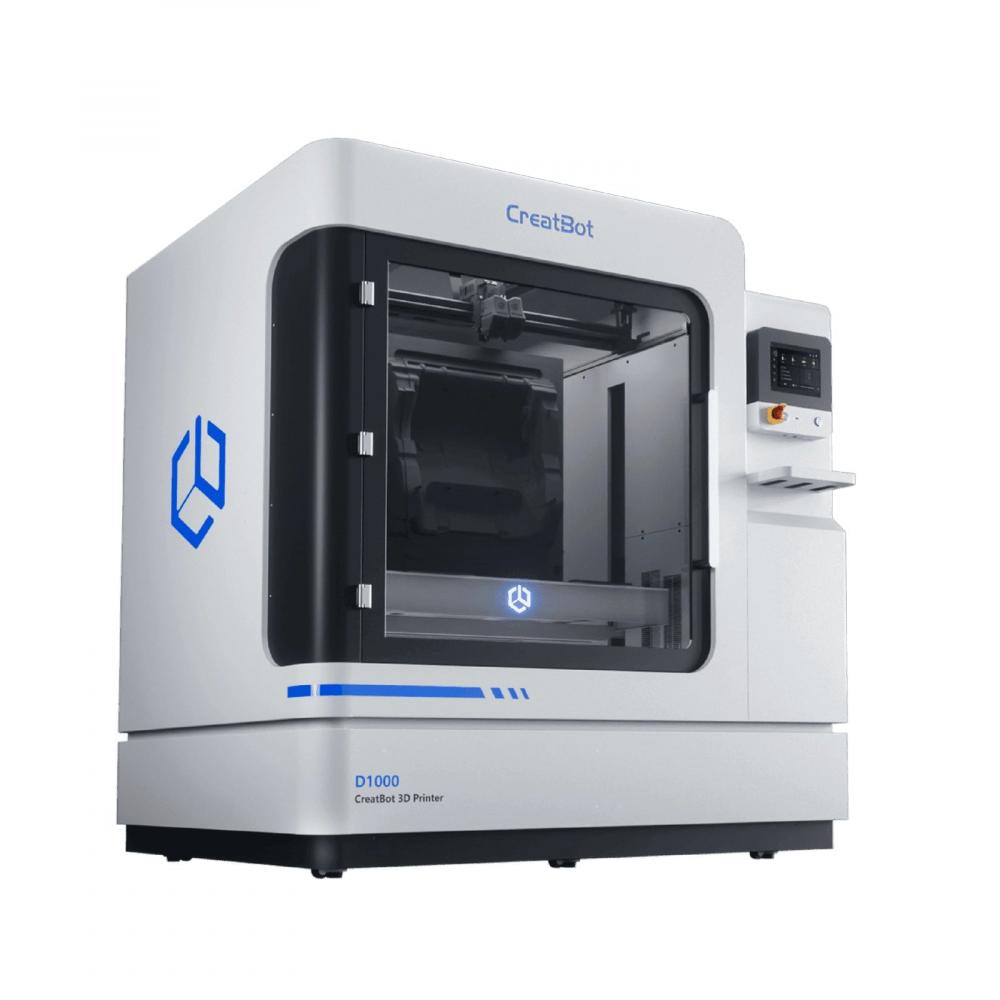

CreatBot D1000

CreatBot D1000

Couldn't load pickup availability

Industrial large-format 3D printer with one cubic meter build volume

The CreatBot D1000 is the advanced version of the F1000 model and offers an impressive build volume of over 1000 x 1000 x 1000 mm. This makes it the ideal machine for producing large-format and full-scale parts, prototypes, tools, molds, fixtures, and mounts directly on-site. You can create functional, high-quality prototypes within just a few days. The CreatBot uses large filament spools made of materials such as PLA, ABS, ASA, and PA-CF, so you don't have to worry about frequent filament changes. Every feature of the D1000 is engineered for the highest quality—for perfect results every time, without errors.

Use in the automotive industry

Faurecia, a global leader in advanced automotive systems and equipment, successfully uses the CreatBot D1000 3D printer to develop and design car seat molds. These molds are used by Audi, VW, Nissan, and GM Motors, among others. In the video, you can see typical 3D-printed products produced with the D1000. The bowl and lid must withstand a pressure of 100 MPa, which is why we chose nylon-carbon fiber materials with 50% infill for production. The prints demonstrated excellent performance and passed all rigorous tests!

Size-independent for high-strength prototypes

The CreatBot D1000 is designed to make industrial 3D printing of large-format objects and prototypes as easy as possible. Equipped with cutting-edge technology for impressive XXL prints, it is undoubtedly the best choice if you're looking for an industrial large-format 3D printer for prototypes and technical materials.

Revolutionary material for stable prints

If you're tired of the fragility of PLA and the warping of ABS, try our revolutionary material UltraPA-CF. Print your large-format model with a large nozzle, and within a few days you'll have an oversized model with high strength of 80 MPa and a temperature resistance of 150°C. The best choice for your prototype verification.

Automatically lifting dual extruders with 420 °C

The D1000 is equipped with a new intelligent dual extruder kit that automatically raises and reaches a hotend temperature of up to 420°C. The hotend can be quickly replaced with different nozzles. It not only prints large prototypes in PLA with water-soluble PVA material at high speed, but also ABS, PC, nylon, carbon fiber, flexible materials, and many other high-performance materials for direct applications. The dual extruder is easy to maintain and inexpensive to replace.

Power failure recovery & filament detection

The printer automatically saves the current position and saves the print data if the power supply is suddenly interrupted. It lowers the platform and retracts the filament. After powering on, it seamlessly resumes printing from the last point – without leaving any traces! The printer prevents erroneous printing by stopping the print and warning you when the filament runs out.

Linear rails and servo motors

At lengths over 1000 mm, small rails can experience significant deformation. However, the D1000's precise linear rail structure is extremely thick and stable. It resists deformation and accuracy loss even after millions of printhead impacts. Servo motors ensure fast response times, eliminating inertia or lag. Closed-loop position control eliminates the problem of lost steps. Heat and noise are significantly reduced, ensuring outstanding high-speed printing performance.

Heating chamber + filament drying room

The 60°C hot chamber ensures print quality for high-performance materials. The fully enclosed enclosure blocks out all external influences and reduces noise while maintaining a constant temperature to prevent model deformation. The filament drying chamber offers chamber temperatures of 45°C and 65°C for drying 2x5kg rolls of filament such as PLA, nylon, PC, ABS, and other water-absorbent materials.

Automatic leveling of the platform

By utilizing 100 measurement points with a high-precision servo sensor, the printer saves the platform flatness data at the beginning of printing. During the printing process, the Z-axis height is intelligently compensated to ensure fully automatic leveling.

HEPA air filter

The air filtration system can absorb contaminants and gases generated when printing with special filaments such as ABS, nylon, or PC. This ensures greater safety and environmental protection, making the printer ideal for use at home, in schools, and in offices.

Camera technology for remote control

Camera technology allows customers to remotely control the printing process via an app. Speed, pauses, temperature, and other parameters can be adjusted to achieve the best print quality in the shortest time and without errors. This feature is especially useful for large models and long print times.

Affordable and reliable large format 3D printer

The CreatBot D1000 was developed to make industrial 3D printing of large-format objects and prototypes as easy as possible. In response to market demands, this industrial 3D printer is equipped with a new intelligent dual-extruder kit, a closed heated chamber, an automatic leveling system, and camera control for impressively large prints. The camera technology allows customers to control the printing process via an app, achieving the best print quality in the shortest possible time and without errors. With a fast-heating platform and hot chamber, this high-resolution large-format printer produces stunning results with high-quality materials. The CreatBot D1000 sets new standards in additive manufacturing and expands the material possibilities for large-format 3D printers, enabling companies to significantly save costs and time.

Reliable stability

The D1000's all-steel housing not only ensures stability during printing but also significantly extends the device's service life. Optimization and tuning of the entire structure ensure sustainable and efficient operation. The first series of CreatBot 3D printers with all-steel housings has been in operation for nine years and has achieved over 30,000 operating hours.

Share